How to choose a machine for gutter production

Regardless of the equipment required, you should always consult a specialist. Only a professional will be able to answer questions and help in choosing the equipment that is ideal for the required work.

Experts of company Stangroup will help you if you want to buy machine tools for manufacture of a metal tile, a siding, a professional flooring, drain pipes.

Profile bending lines

Before starting the rolling business, it should be understood that metal profiling is different in such nuances:

- This is a seasonal work, because manufactured goods are needed only during the period of active construction.

- Optimal profit the owner can earn only on large volumes.

- If necessary, produce profiles, curved more than 30 degrees, you need a three-roller unit.

- The quality of goods must be at the highest level.

The machine for the manufacture of skates and tides should be selected particularly carefully. This equipment is designed for the production of good elements of the roof, facades and tides. A special advantage of such a machine – mobility and low weight. Choosing a machine tool and production technology, you should contact directly to the seller of the equipment. Specialists will help you choose the right equipment, taking into account the specifics of the buyer’s production and tasks.

The system for water drainage with a circular cross-section consists of several elements mounted on the roof and facade of the building. To produce the elements of the roof, you will also need machines for gutters of shaped sections. The gutter system will protect the building from most rainfall by collecting and draining water. It is worth choosing a machine for the manufacture of gutters only from proven manufacturers and distributors. Otherwise, the buyer runs the risk of getting a poor quality product, spending a lot of money on it.

Advantages of equipment for the production of roofing

Ease of use of equipment for metal tiles allows you to produce a profile directly on the site of construction work. Machines produce billets of the desired length, rolling them manually – a guarantee of material integrity. The method guarantees silent operation with high productivity. Thus, it is possible to avoid damage to the sheets during transportation.

The machine for metal tile has 7 main advantages:

- Relatively low weight and parameters.

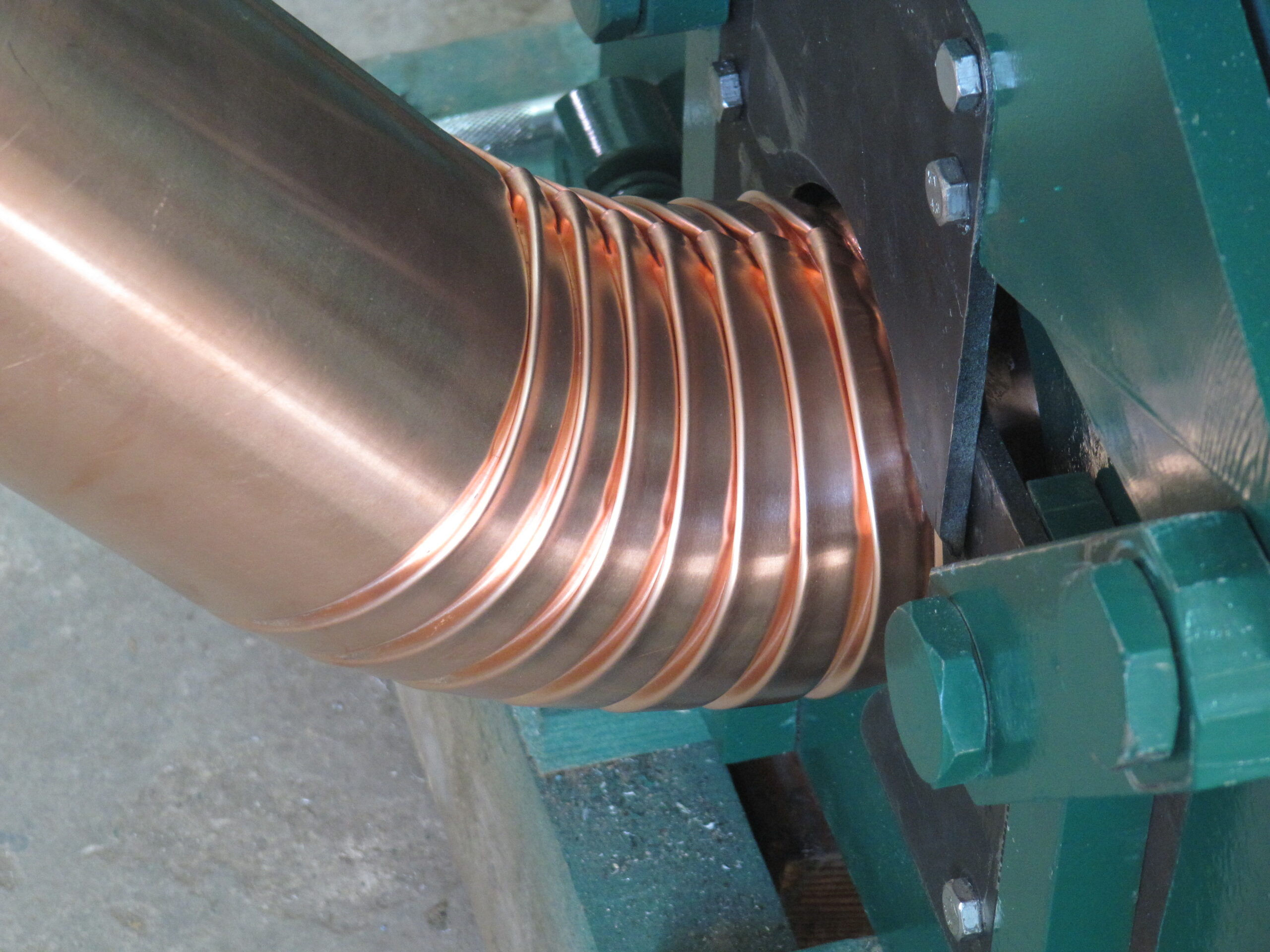

- The rollers in the correct configuration avoid deformation. This is relevant for achieving precise parameters and shape.

- The material is easily gripped and removed.

- Rolling is carried out on both sides of the sheet to achieve a perfect shape.

- Quick changeover to another width.

- Additional tools for cutting and rolling of stiffeners.

- Ability to work with different metals.

Equipment for the production of metal tiles is worth buying from proven manufacturers who have already proven themselves in the market. Detailed instructions for setting up and operation are available for the machines. If you can not set up the machine yourself, it is better to use the help of a specialist. You can find many excellent products and the best offers at.

Equipment for siding production will help to produce the necessary amount of material right on the construction site. This solution helps to finish the construction without joints, which saves time for installation and improvement of appearance. Buying such a machine will significantly save time on the order and transportation of construction goods. Small overall dimensions of the machine and low power consumption requirements allow to organize the production of the product even in small rooms.

About the author